Japan hydrogen

Faber has been present in Japan for over 20 years with supplies of gas cylinders for automotive, industrial, medical and scuba diving fields. Its endeavor in the Japanese hydrogen sector to offer more cost effective, lighter-inweight solutions has now reached a new milestone.

Faber Industrie continues its journey of developing new and more efficient solutions custom-designed for numerous markets.

Faber has been present in Japan for over 20 years with supplies of gas cylinders for automotive, industrial & medical and breathing apparatus (scuba diving) fields. Its endeavor in the Japanese hydrogen sector to offer more cost effective, lighter-inweight solutions has now reached a new milestone.

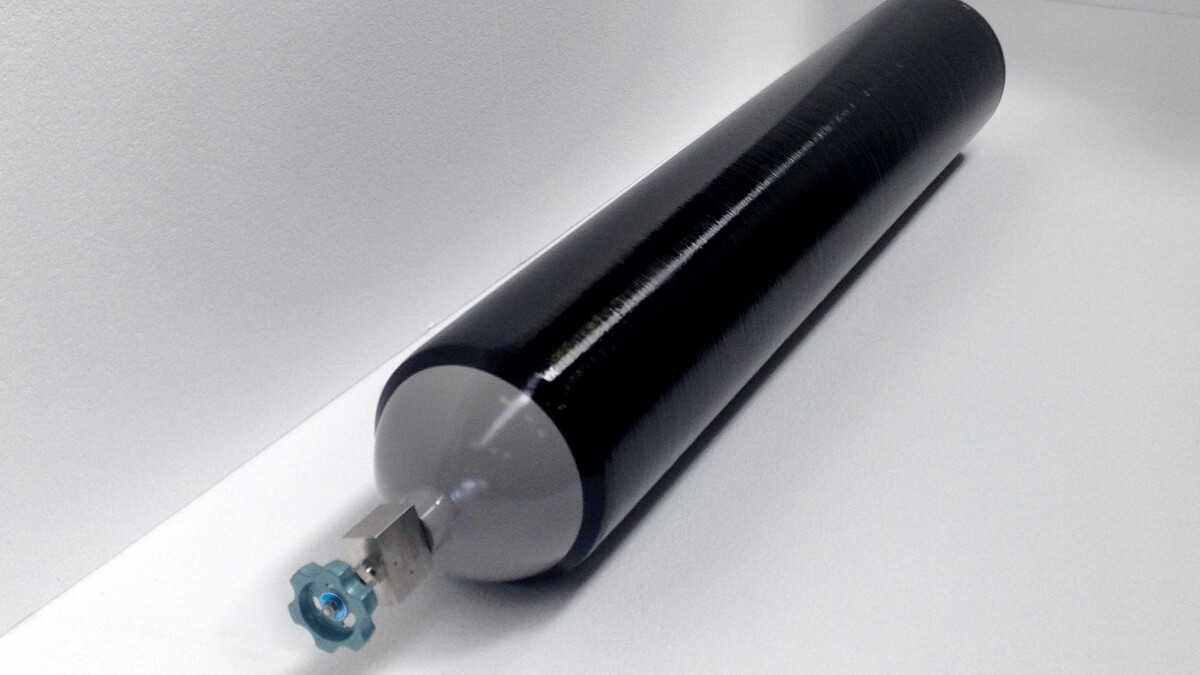

Faber’s Type 1 (56MPa) and Type 2 (100MPa) cylinders for hydrogen stations have been granted KHK Global Approvals (Hōkatsu Nintei) in 2018 and April 2019 respectively. Global Approvals are comprehensive approvals with duration of five years for cylinders with market experiences in Japan, and cover different capacity ranges.

The new achievement allows shorter lead-time for the approval process practiced by The High Pressure Gas Safety Institution of Japan, especially for Type 2 hoopwrapped composite cylinders. In the current existing standards in Japan, Type 2 cylinder as Designated Equipment under High Pressure Gas Act is excluded and in general requires more complex Special Ministerial Approval procedures.

Faber’s presence in Japan for hydrogen station/FCV sectors has been further strengthened through collaborations with OEMs and station owners. Its supplies of Type 1 and Type 2 for stationary application and Type 3 for OEM forklifts have been in place for years thanks to the growing market trends towards the leading hydrogen society and expectations for governmental incentives.

For more information, contact us at sales@faber-italy.com (Japanese/ English)

Established in 1969 and operating since 1972, Faber has grown rapidly to become the world’s leader in the production of cylinders (Types 1, 2, 3 & 4) and systems for the storage of High-Pressure Gases for the Clean Energy (CNG and H2), Industrial and Air Breathing sectors. The world over, with a production capacity of a million cylinders, Faber has earned the best reputation for its high standards of quality and for its capability to comply with the most stringent specifications set down by International Bodies, Local Authorities and its customers.