FABER HAS MASTERED ALL THE TECHNOLOGIES TO DESIGN EFFICIENT AND SAFE GAS CYLINDERS

With the same technical characteristics, Faber’s cylinders are the lightest in the world among both metal and composite cylinders. There are applications for which the Type 1 cylinder is not light enough or because of the very high design pressure or portability. In such cases it is necessary to use composite materials. These can vary depending on the weight to be achieved and the price that the customer and the application can support. The entire production process is controlled by Faber and performed in-house in one of our own dedicated plants. This ensures that Faber is capable of offering the right cylinder at a price that best fits the needs of our customers.

All metal cylinder

A hoop wrapped cylinder with a load sharing metal liner and composite reinforcement on the cylindrical part only

A fully wrapped cylinder with a load sharing metal liner and composite reinforcement on both the cylindrical part and dome ends

A fully wrapped cylinder with a non-load sharing liner and composite reinforcement on both the cylindrical part and dome ends

Type 1

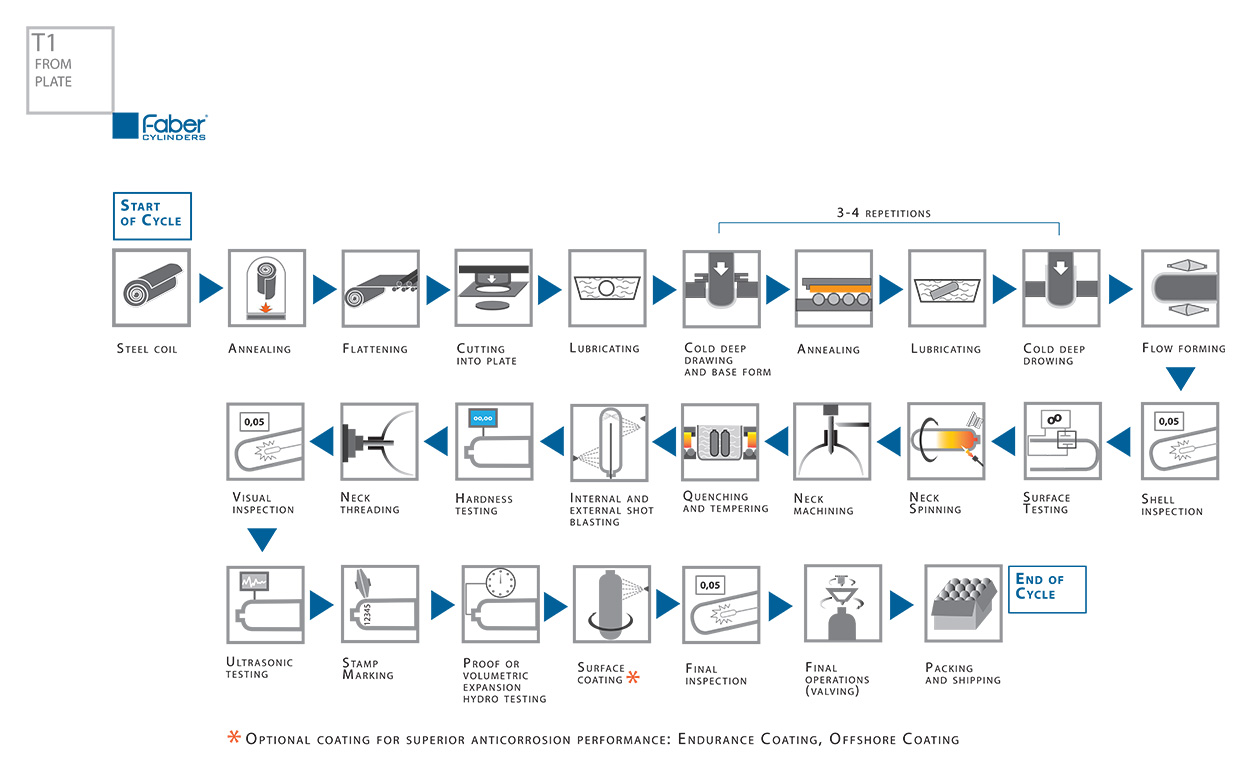

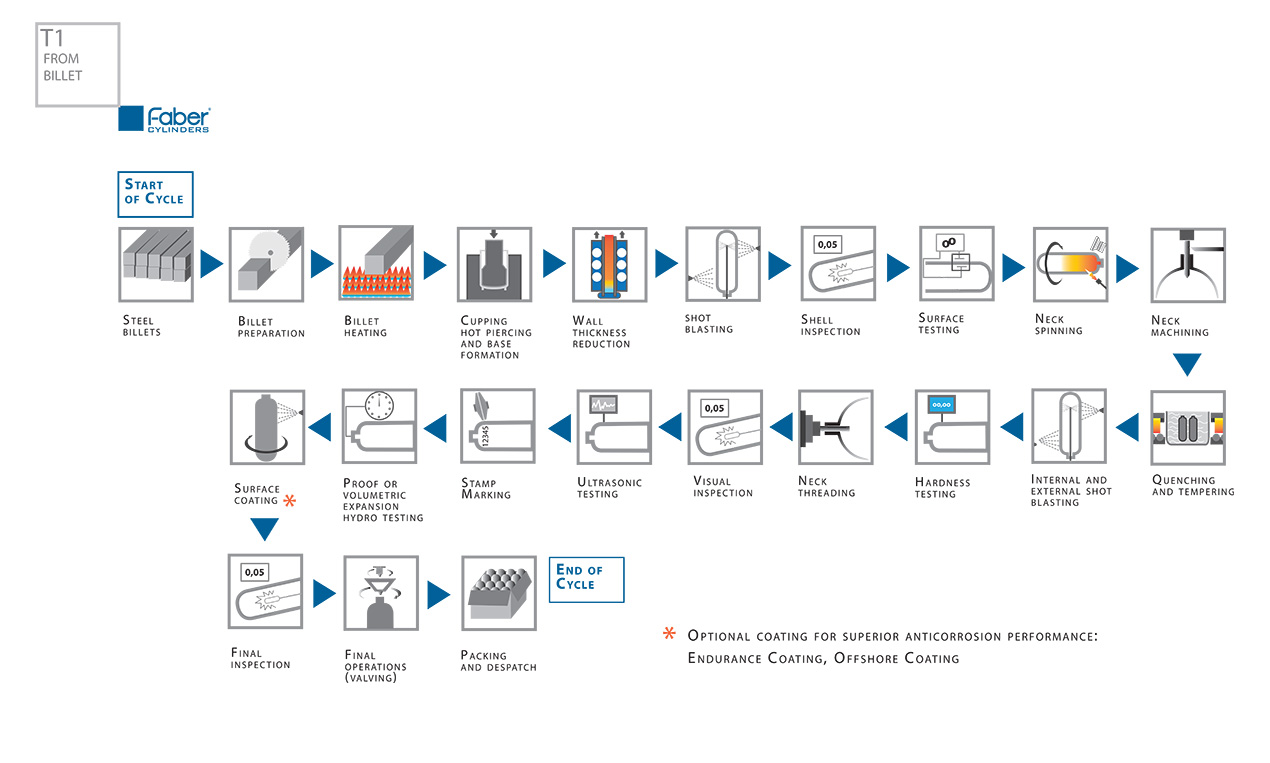

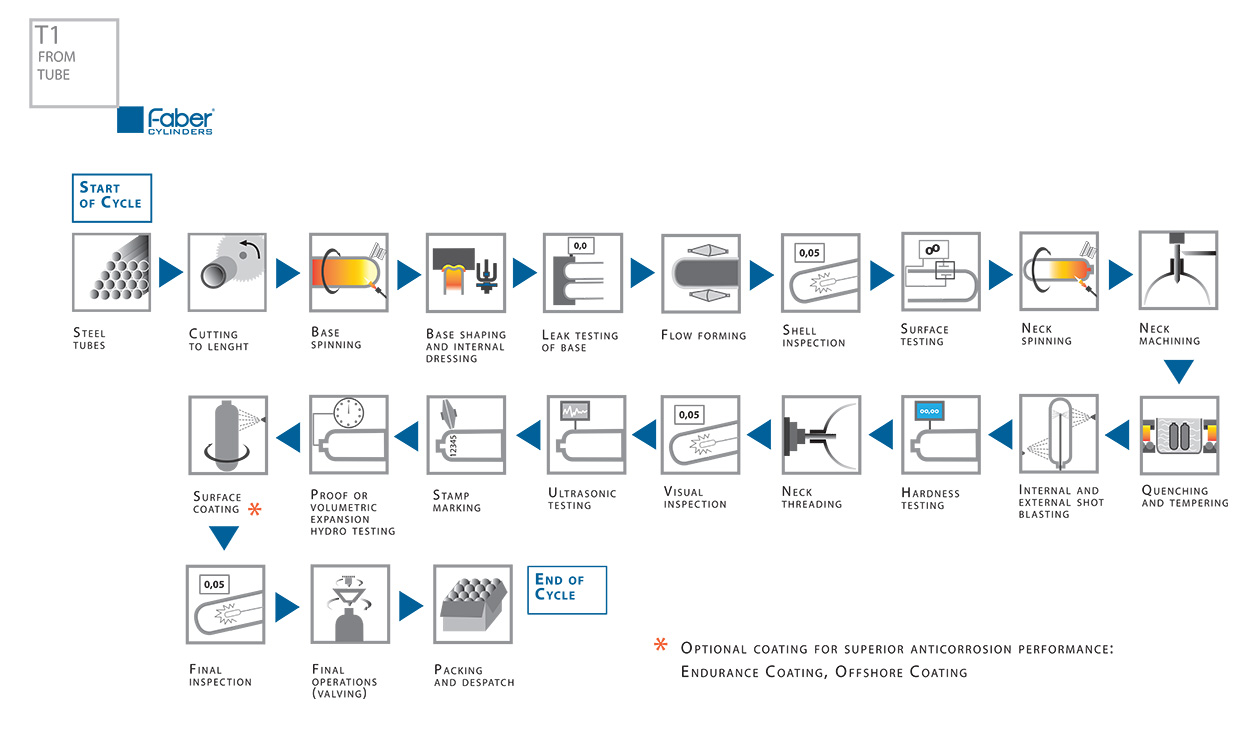

Faber manufactures Type 1 steel cylinders from all of the three stock material sources. The choice made depends on whichever is the most suitable process: from plate or from billet or from tube. The entire production process is controlled by Faber and performed in-house in one of our own dedicated plants. This ensures that Faber is capable of offering the right cylinder at a price that best fits the needs of our customers

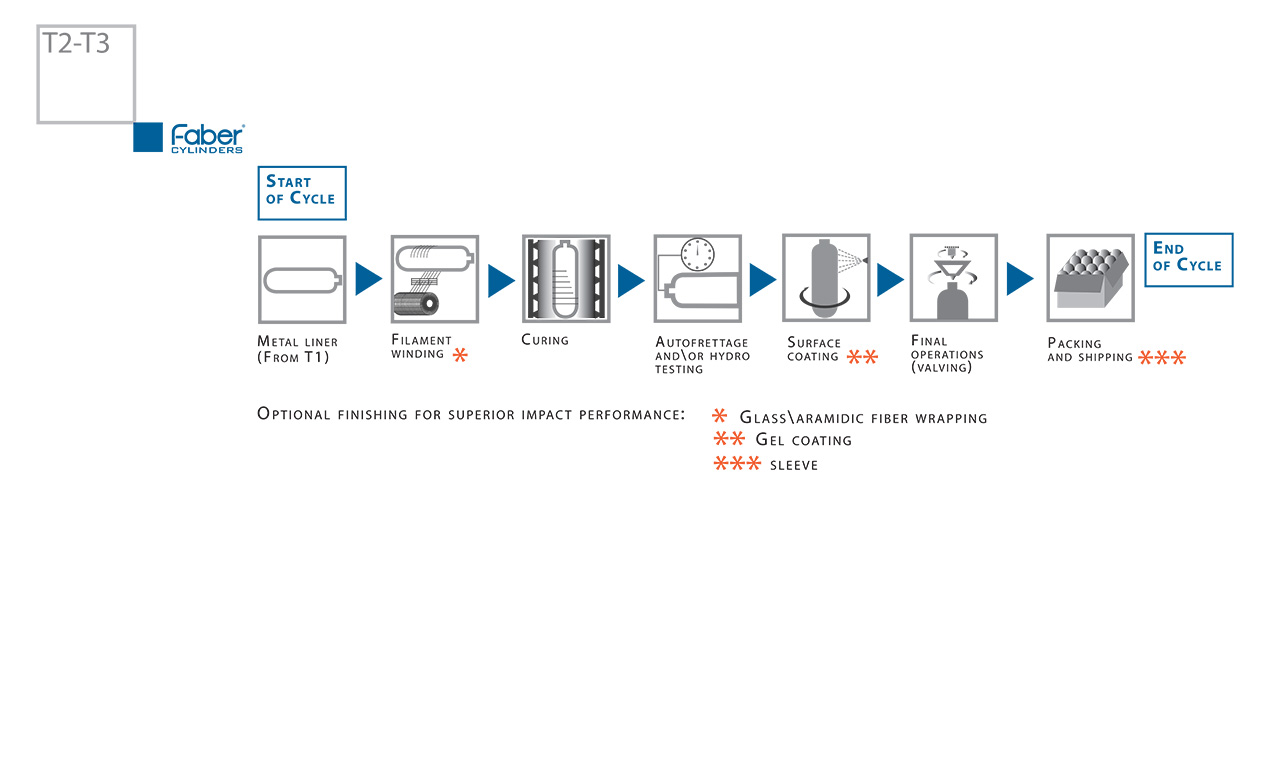

Type 2 and 3

Faber relies on its Type 1 capability to manufacture light metal liners for composite Type 2 and 3 cylinders, which are finished by filament winding and curing of Carbon Fiber Reinforced Plastic. Glass fiber may be mixed with Carbon fiber while winding and/or applied as final layer to the product as a protective shield

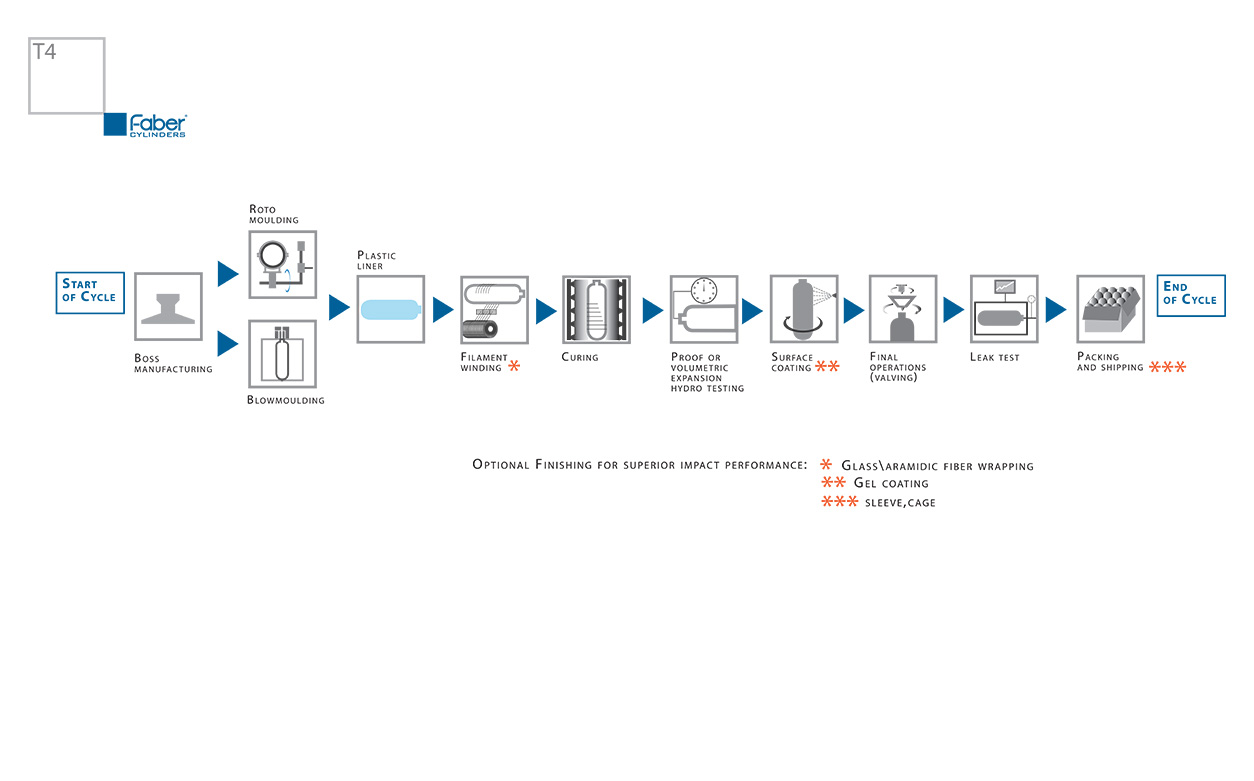

Type 4

Faber has the capability to produce the plastic liner for full composite Type 4 cylinders, which are finished by filament winding and curing of Carbon Fiber Reinforced Plastic. Glass fiber may be mixed with Carbon fiber while winding and/or applied as final layer to the product as a protective shield