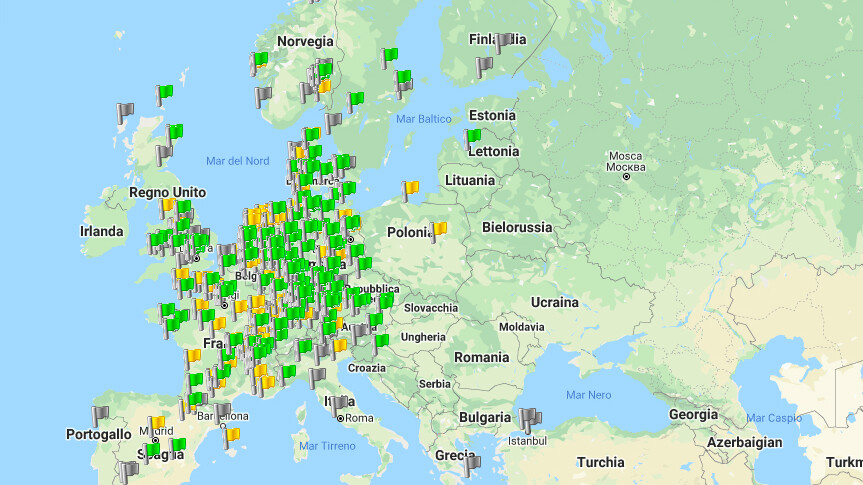

Europe hydrogen refuelling

In Europe there are now more than 100 filling stations for hydrogen applications and most of them run on hydrogen stored in Faber cylinders.

Faber has been present with its cylinders in the hydrogen refuelling stations for more than 10 years thanks to the strong cooperation with the major players in Europe.

Faber in the years enhanced its knowhow driven also by its commitment for sustainability and the real benefits provided by hydrogen in the fight against urban pollution.

Type 1 and type 2 cylinders have been developed to comply with the customer request for high pressure and to accommodate the pressure cycles needed for the vehicle refuelling.

The cylinder service pressure increased in the time from 850bar to 1000bar and for special cases up to 1100bar to obtain efficient fillings operation. Faber cylinder sizes provide the possibility to optimize the space for the hydrogen storage when installed inside the filling station to obtain compact filling stations. The same concept has been applied to Faber hydrogen buffers to provide a compact hydrogen storage footprint for low pressure buffers (200bar or 300bar), medium pressure buffers (550bar) and high pressure buffers (1000bar or 1100bar) available in modular solutions with different capacity to scale up based on customer request.

In Europe there are now more than 100 filling stations for hydrogen applications and most of them run on hydrogen stored in Faber cylinders.

Established in 1969 and operating since 1972, Faber has grown rapidly to become the world’s leader in the production of cylinders (Types 1, 2, 3 & 4) and systems for the storage of High-Pressure Gases for the Clean Energy (CNG and H2), Industrial and Air Breathing sectors. The world over, with a production capacity of a million cylinders, Faber has earned the best reputation for its high standards of quality and for its capability to comply with the most stringent specifications set down by International Bodies, Local Authorities and its customers.