Hydrogen

Hydrogen is the lightest gas with the smallest atom and with many other unique properties. In recent years it has been gaining favour as a “green gas” with an application as an alternative, zero-emission fuel in the automobile industry. Hydrogen is also seen as the preferred energy carrier for Energy Storage applications.

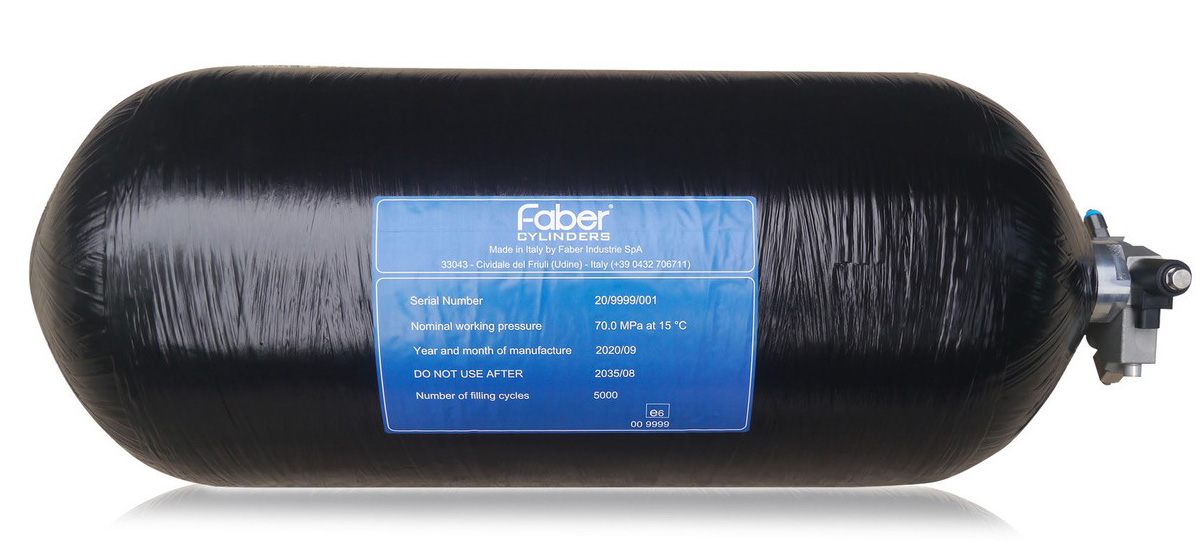

Hydrogen can also be an embrittling gas and thus has to be used taking great care with respect to the characteristics of the container material to prevent any hydrogen induced cracking. Hence Faber has, over the years, followed well established principles (see EN ISO 9809-1 and EN ISO 11114-1, -4) such as using steels, whose tensile strength is limited to a maximum of 950 MPa for cylinders with working pressures of around 250 bar and a range of non-destructive tests to ensure that no deleterious imperfections (which if present could lead to a premature failure) are present. However, for fuel gas applications where working pressures around 1000 bar can prevail, Faber has developed its own high pressure hydrogen research. This development facility, based at one of their manufacturing locations in Cividale, Italy, ensures that only safe materials are ever used. The safety is ensured not only for Faber’s seamless (Type 1) hydrogen cylinders, but also for our Types 2,3 cylinders, which are steel lined and Type 4 (plastic lined) vessels. Faber has also designed and engineered the integration of the cylinders (i.e. Racks, Bundles, Multi Element Gas Containers, Containers) in order to provide ready to use storage systems.

Members of Faber’s Technical Department are active participants in a number of European hydrogen initiatives. These have included Storhy and Hycomp projects.

Our hydrogen cylinders are used throughout the world in a wide variety of storage applications by a host of different customers. Being the only worldwide manufacturer of all four Types (1,2,3,4) of hydrogen cylinders and systems, our customers use them for static storage, industrial applications, refilling stations, fuel cell usage and of course transport just to mention a few. The other unique aspect of Faber’s cylinders, is the fact we manufacture not only the shells, but also fabricate in-house, the liners for all Types of composites. Depending on the eventual use, Faber caters for a number of working pressures from the usual 200 bar for industrial users to 1100 bar when used for storage and a corresponding range of manufacturing standards/regulations. The latter include the widely used ISO 11119 series, EN 12245, EN 12257, UNECE Reg 134, EC79, ASME Section VIII Division I and III, ISO 19881, ISO 15869, EN 17533, EN 17339, JARI S 001 etc. All our cylinders are fully manufactured in-house and also certified/tested in our newly equipped test laboratory, by third party inspection bodies who have been appointed by Competent Authorities (Government).

Hydrogen requires all four types of cylinders depending on the final application. This is why Faber is your one stop supplier!

We will be happy to assist you

for any inquiry at info@faber-italy.com

FABER CYLINDERS

Faber production covers all Cylinder Types:

Type 1 Steel¹ Cylinders

Type 2 Steel¹/Fibre Composite Cylinders

Type 3 Steel¹ & Aluminum¹/Fibre Composite Cylinders

Type 4 Full Composite Cylinders

¹ Faber Type 1, Type 2, Type 3, from 100% Seamless Steel & Aluminum

Faber production range:

from 1 to 700 litre water capacity

from 80 to 660 mm diameter

up to 1100 bar Working Pressure

DATABASE & DRAWINGS

Faber is leader in the production of seamless steel and composite cylinders.

You can access our database and print diving cylinders drawings, please login.